The Road to a

More Sustainable Future

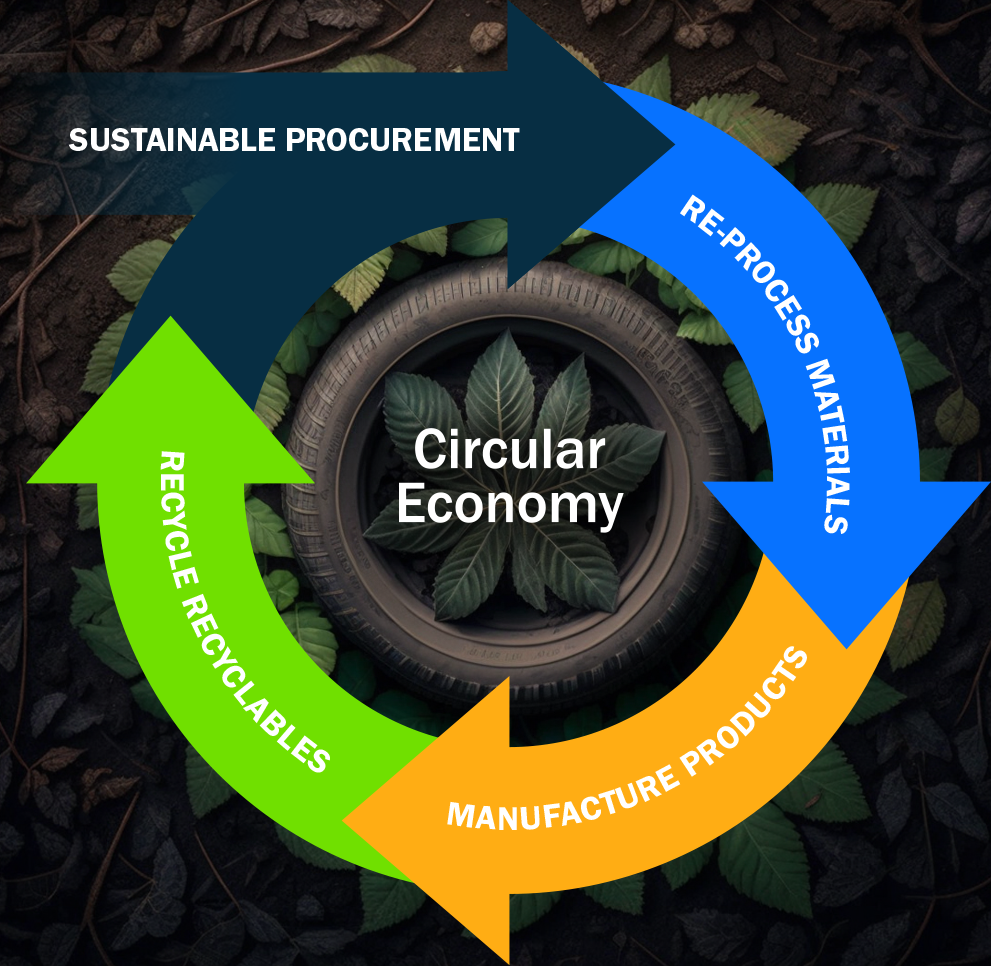

Our mission is to lead the way towards a truly circular economy by utilising cutting-edge technologies and ethical practices to recycle and upcycle end of life tyre waste.

Our Partners

Our Circular Approach

to Sustainability

We're dedicated to creating sustainable and environmentally conscious products by repurposing end-of-life tyres through a unique circular process. Our innovative approach allows us to manufacture durable and eco-friendly products while also providing a sustainable solution for rubber material.

By choosing our products, you can positively impact the environment and contribute to a more sustainable and circular economy future.

Our Services

Our Innovative Process

Our fully-circular process for repurposing end of life tires uses cutting-edge technology to create high-value black rubber compounds. We decontaminate the rubber and recycle scrap steel, categorizing the resulting polymer for shipping to customers. We use these recycled rubber compounds to create new, eco-friendly products at our manufacturing facility. This way, we contribute to a more sustainable future while providing customers sustainable products.

MADE FROM LOCALLY SOURCED RECYCLED RUBBER

Innovative products

with sustainable impact

We have partnered with global award-winning cleantech organisations to license their manufacturing technology, allowing us to create valuable commodities and products in various jurisdictions. Our manufacturing is divided into two main areas: repurposing and processing of waste tyre crumb into functionally modified rubber particulate for the roads, paving and construction industry.

In addition, we employ moulding technology that uses pressure and heat to create everyday consumer, commercial and industrial products which are all re-recyclable at their end of life. Through these focus areas, REVYRE is committed to transforming waste tyres into valuable commodities and products while promoting environmental sustainability and reducing the negative impact of waste on our planet.

RECYCLED RUBBER DISTRIBUTION

Where the rubber meets the road

We manufacture and distribute REVPOL to wholesalers or businesses who directly consume high quality material, where previously they required virgin Natural rubber (NR) or Synthetic Rubber (SBR/S).

Use cases for this product include roading/pavements, construction, custom compounding, automotive industry for parts, i.e. engine mounts, gaskets, seals, new tyres, retreads, and agriculture for Agri matting for improved animal welfare.

Benefits

-

Fully Circular

End-of-life tyre compounds are re-used to create new tyres or alternative products.

-

Sustainable

Our process is environmentally clean and sustainable.

-

Upcycle & Recycle

We upcycle end-of-life tyre waste and recycle again.

-

No Toxic Waste

We produce no toxic waste by completely reprocessing the tyre and other rubber products.

-

Low CO2 Emissions

We have low CO2 emissions through our reprocessing practises.

-

Reduce GHG Emission

By substituting virgin raw materials with recycled rubber compounds, our process reduces GhG emissions.

Latest News

Get in touch.

Contact us now to learn more about our repurposing process and start your sustainability journey today. Fill out our contact form and one of our experts will get back to you as soon as possible.